Contact person: tony.wang

Address: No 65 Science Avenue, HI-TECH Zone, Zhengzhou, China

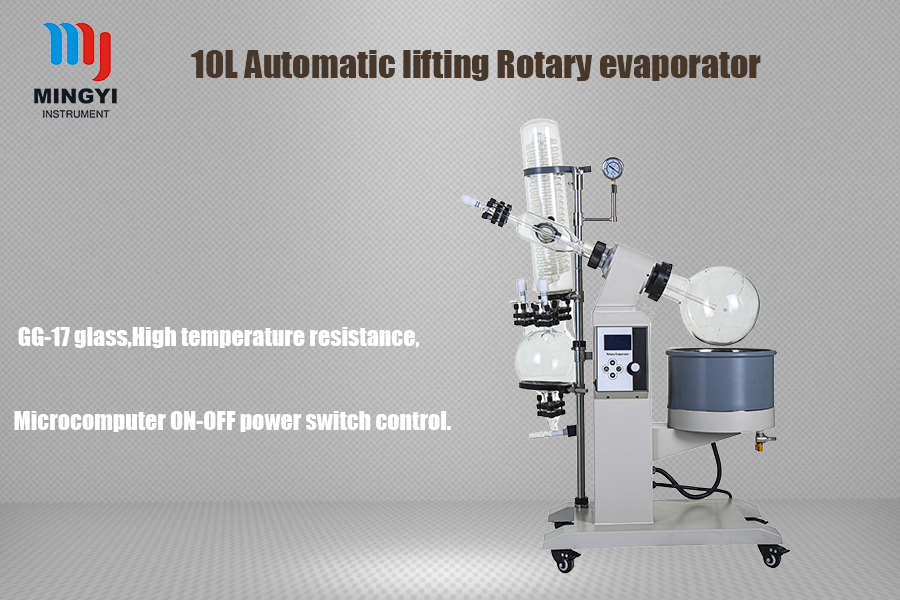

10L Rotary evaporator is mainly used in the concentration, crystallization, drying, separation and solvent recovery of pharmaceutical, chemical and biological pharmaceutical industries.

| Availability: | |

|---|---|

| Quantity: | |

Brief Introduction of the 10L Automatic Lifting Rotary Evaporator:

Brief Introduction of the 10L Automatic Lifting Rotary Evaporator:10L Rotary evaporator is mainly used in the concentration, crystallization, drying, separation and solvent recovery of pharmaceutical, chemical and biological pharmaceutical industries. Its principle is: under vacuum condition, constant temperature heating makes the rotary bottle rotate at constant speed, and the material forms large area film on the bottle wall, so it can be evaporated efficiently. The solvent evaporation is cooled by the high-efficiency glass condenser and recovered in the collecting bottle, so as to greatly improve the evaporation efficiency. The utility model is especially suitable for concentrating and purifying biological articles with high temperature and easy decomposition and degeneration.

Brief Introduction of the 10L Automatic Lifting Rotary Evaporator:

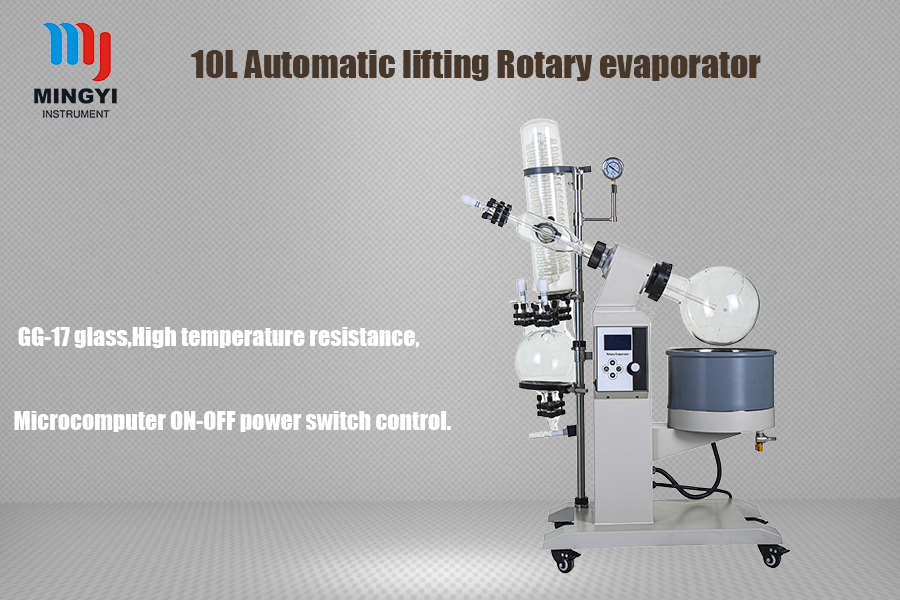

Brief Introduction of the 10L Automatic Lifting Rotary Evaporator:10L Rotary evaporator is mainly used in the concentration, crystallization, drying, separation and solvent recovery of pharmaceutical, chemical and biological pharmaceutical industries. Its principle is: under vacuum condition, constant temperature heating makes the rotary bottle rotate at constant speed, and the material forms large area film on the bottle wall, so it can be evaporated efficiently. The solvent evaporation is cooled by the high-efficiency glass condenser and recovered in the collecting bottle, so as to greatly improve the evaporation efficiency. The utility model is especially suitable for concentrating and purifying biological articles with high temperature and easy decomposition and degeneration.

1, The main body of the use of stainless steel + aluminum alloy, reasonable structure, materials stress.

2, Sealing system using PTFE and imported fluorine rubber combination seal, to maintain high vacuum.

3, Vacuum pressure gauge shows real-time vacuum, vacuum up to 0.098Mpa.

4, Glass parts are all high borosilicate glass (GG-17), high temperature, anti-corrosion.

5, Can be continuously fed to facilitate the use of customers, valve-type feeding tube sets of tetrafluoroethylene tube.

6, Vertical three-tier serpentine coil condenser, the main cold + pay cold double condenser, to ensure high recovery rate, additional tube.

7, Microcomputer ON-OFF power switch control.

8, Bath digital display, intelligent thermostat control, K-type sensor fast and accurate delivery temperature.

9, Frequency control (0-120rpm), speed digital display, knob set, easy to operate.

10, Fuse safety protection.

11, The pot is made of high quality stainless steel, durable and durable.

12, Bath handwheel lift.

13, Collection of bottles with a discharge material, easy to evaporate the collection of extracts, discharge.

14, Check valve control, continuous discharge.

1, The main body of the use of stainless steel + aluminum alloy, reasonable structure, materials stress.

2, Sealing system using PTFE and imported fluorine rubber combination seal, to maintain high vacuum.

3, Vacuum pressure gauge shows real-time vacuum, vacuum up to 0.098Mpa.

4, Glass parts are all high borosilicate glass (GG-17), high temperature, anti-corrosion.

5, Can be continuously fed to facilitate the use of customers, valve-type feeding tube sets of tetrafluoroethylene tube.

6, Vertical three-tier serpentine coil condenser, the main cold + pay cold double condenser, to ensure high recovery rate, additional tube.

7, Microcomputer ON-OFF power switch control.

8, Bath digital display, intelligent thermostat control, K-type sensor fast and accurate delivery temperature.

9, Frequency control (0-120rpm), speed digital display, knob set, easy to operate.

10, Fuse safety protection.

11, The pot is made of high quality stainless steel, durable and durable.

12, Bath handwheel lift.

13, Collection of bottles with a discharge material, easy to evaporate the collection of extracts, discharge.

14, Check valve control, continuous discharge.

Basic parameter | Model | RE-1002 |

Glass material | GG-17 | |

Holder material | Stainless steel | |

Pot material | Spray corrosion 490*430*540mm | |

Pot guts Material | Stainless steel 350*220mm | |

Plate size | 474*474mm | |

Rotary bottle volume | 10L ¢95 flanged | |

Collective bottle volume | 5L ¢50 flanged | |

Vacuum | 0.098Mpa | |

Rotary power | 120W | |

Rotary speed | 0-110rpm | |

Heating power | 3KW | |

Bath temp. range | 0-400℃ | |

Temp. control accuracy | ±1℃ | |

Voltage(V/Hz) | 220V/50Hz | |

Lifting stroke | 180mm | |

Size (mm*mm*mm) | 970*480*1950mm | |

Packing size(mm*mm*mm) | 1350*350*400 1280*570*660 0.67m2 | |

Gross weight(KG) | 100 | |

Function | Speed mode | Frequency Control |

Speed display | Digital display6 | |

Temp. control mode | K type sensor digital display | |

Temp. control | Intelligent temperature control | |

Sealing method | Tetrafluoroethylene seal assembly | |

Condenser | Vertical efficiency three reflux condenser, main condenser 120 * 640, 135 * 470 pay cold | |

Continuous collection | Valve control | |

Lifting mode | Manual lifting bath pot | |

Temperature measuring device | 19# standard port | |

Continuous feed | 34 # standard port feed valve | |

Discharge mode | Tetrafluoroethylene discharge valve, ¢ 50 flanged | |

Vacuum display | Vacuum table | |

Optional | Lifting mode | Automatic lifting |

Collective mode | Double collective bottle | |

Explosion proof | Proof inverter, explosion-proof motor EX120W | |

Frame portion | Spray or spray tetrafluoroethylene | |

Bath material | 304 stainless steel |

Basic parameter | Model | RE-1002 |

Glass material | GG-17 | |

Holder material | Stainless steel | |

Pot material | Spray corrosion 490*430*540mm | |

Pot guts Material | Stainless steel 350*220mm | |

Plate size | 474*474mm | |

Rotary bottle volume | 10L ¢95 flanged | |

Collective bottle volume | 5L ¢50 flanged | |

Vacuum | 0.098Mpa | |

Rotary power | 120W | |

Rotary speed | 0-110rpm | |

Heating power | 3KW | |

Bath temp. range | 0-400℃ | |

Temp. control accuracy | ±1℃ | |

Voltage(V/Hz) | 220V/50Hz | |

Lifting stroke | 180mm | |

Size (mm*mm*mm) | 970*480*1950mm | |

Packing size(mm*mm*mm) | 1350*350*400 1280*570*660 0.67m2 | |

Gross weight(KG) | 100 | |

Function | Speed mode | Frequency Control |

Speed display | Digital display6 | |

Temp. control mode | K type sensor digital display | |

Temp. control | Intelligent temperature control | |

Sealing method | Tetrafluoroethylene seal assembly | |

Condenser | Vertical efficiency three reflux condenser, main condenser 120 * 640, 135 * 470 pay cold | |

Continuous collection | Valve control | |

Lifting mode | Manual lifting bath pot | |

Temperature measuring device | 19# standard port | |

Continuous feed | 34 # standard port feed valve | |

Discharge mode | Tetrafluoroethylene discharge valve, ¢ 50 flanged | |

Vacuum display | Vacuum table | |

Optional | Lifting mode | Automatic lifting |

Collective mode | Double collective bottle | |

Explosion proof | Proof inverter, explosion-proof motor EX120W | |

Frame portion | Spray or spray tetrafluoroethylene | |

Bath material | 304 stainless steel |

Contact person: tony.wang

Email:tony.wang@mingyint.com

kevin.wang@mingyint.com

Address: Room 1002 10/F, Easey, Commercial Building 253-261 Hennessy Road WanChai, HK.

Address: No.65 Science Avenue,HI-TECH Zone,Zhengzhou,China.