Contact person: tony.wang

Address: No 65 Science Avenue, HI-TECH Zone, Zhengzhou, China

Views: 6 Author: Site Editor Publish Time: 2021-09-28 Origin: Site

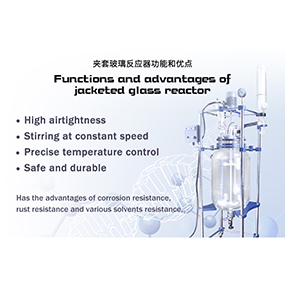

The glass reactor is composed of a kettle body, a kettle cover, a jacket, a stirrer, a transmission device, a shaft sealing device, and a support.

The stirring form generally includes anchor type, paddle type, turbine type, propeller type or frame type, etc. When the height of the stirring device is relatively large, multiple stirring blades can be used, or it can be arbitrarily selected according to user requirements.A jacket is arranged outside the wall of the kettle, or a heat exchange surface is arranged in the vessel, and heat exchange can also be carried out through an external circulation. Heating methods include electric heating, hot water heating, heat-conducting oil circulation heating, far-infrared heating, outer (inner) coil heating, etc. The cooling methods are jacket cooling, kettle inner coil cooling, and stirring blades. The supporting seat has a supporting type or an ear type supporting seat and so on. A gear reducer should be used if the speed exceeds 160 revolutions. The number of holes, specifications or other requirements can be designed and manufactured according to user requirements.

The operation guide for the glass reactor is as follows:

1. In the reaction of different media in the glass reactor, first check whether the media corrodes the main material. Special orders are required for instantaneous reactions that produce a large amount of gas or high-temperature, flammable and explosive chemical reactions, and high-pressure, high-temperature or medium containing chloride and fluoride ions that cause severe corrosion to stainless steel! Special orders are required! Except for transparent glass, the others are stainless steel or other metal materials.

2. When loading the reaction medium, it should not exceed 2/3 of the liquid level of the kettle body!

3. During or at the end of work, it is strictly forbidden to disassemble under pressure! It is strictly forbidden to work under over pressure or over temperature!

4. The jacket heat-conducting oil is heated. When adding heat-conducting oil, be careful not to mix water or other liquids into it. Check the oil level of the heat-conducting oil from time to time!

5. If there is an abnormal sound inside the isolation sleeve during operation, stop and release the pressure, and check whether the mixing system is abnormal. Regularly check the swing of the mixing shaft. If the swing is too large, the bearing or sliding sleeve should be replaced in time!

6. Connect the corresponding voltage according to the operating voltage of the controller, single-phase 220V, three-phase 380V, and the live wire and neutral wire of the controller should not be connected reversely; do not implement wiring work during power transmission to prevent electric shock. In order to ensure the normal operation of the controller and the personal reliability of the staff, please connect the grounding wire. The controller itself is not explosion-proof, so it should avoid flammable and explosive environments such as oil and gas!

7. When the final reaction temperature is determined, the temperature setting value is not allowed to be changed during the heating process, so as to avoid a large overshoot in the temperature!

Contact person: tony.wang

or +86 135 9808 9226

Email:tony.wang@mingyint.com

admin@mingyilab.com

Address: Guanyun Middle Road,Zhuozhou City,Hebei,China.

Address: No.65 Science Avenue,HI-TECH Zone,Zhengzhou,China.