Contact person: tony.wang

Address: No 65 Science Avenue, HI-TECH Zone, Zhengzhou, China

Views: 28 Author: Site Editor Publish Time: 2021-10-19 Origin: Site

Molecular distillation is a special liquid-liquid separation technology. It is different from the traditional distillation which relies on the separation principle of boiling point difference, but relies on the difference of the mean free path of the molecular motion of different substances to achieve separation.

When the liquid mixture flows along the heating plate and is heated, light and heavy molecules will escape from the liquid surface and enter the gas phase. Because the free paths of light and heavy molecules are different, the molecules of different substances move different distances after escaping from the liquid surface. If a condensing plate can be properly set up, light molecules reach the condensing plate and be condensed and discharged, while heavy molecules cannot reach the condensing plate and are discharged along the mixed liquid. In this way, the purpose of material separation is achieved.

The pressure difference between the boiling film and the condensing surface is the driving force of the steam flow, and a slight pressure drop will cause the steam to flow. Operation under 1mbar requires a very short distance between the boiling surface and the condensing surface. A distiller based on this principle is called a short-path distiller. The short path distiller (molecular distillation) has a built-in condenser on the opposite side of the heating surface and reduces the operating pressure to 0.001 mbar.

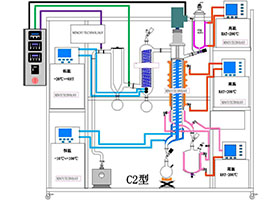

The short path distiller is a thermal separation process that works at a pressure of 1 to 0.001 mbar. Its lower boiling temperature is very suitable for heat-sensitive and high-boiling substances. Its basic composition: a cylindrical cylinder with a heating jacket, a rotor and a built-in condenser; a film wiper and an anti-splash device are accurately installed on the rotor's fixed frame. The built-in condenser is located in the center of the evaporator, and the rotor rotates between the cylindrical barrel and the condenser.

Short-path distiller consists of an externally heated vertical cylinder, a central condenser located in it, and a film wiper rotating between the distiller and the condenser.

The distillation process is: the material is added from the top of the evaporator, and it is continuously and evenly distributed on the heating surface through the material-liquid distributor on the rotor, and then the film-scraper scrapes the material liquid into an extremely thin, turbulent liquid film , And advance downward in a spiral. In this process, the light molecules escaping from the heating surface are condensed into liquid on the built-in condenser through a short route and almost without collision, and flow down the condenser tube through the discharge tube located at the bottom of the evaporator Discharge; the residual liquid, the heavy molecules, is collected in the circular channel under the heating zone, and then flows out through the side discharge pipe.

Contact person: tony.wang

Email:tony.wang@mingyint.com

kevin.wang@mingyint.com

Address: Room 1002 10/F, Easey, Commercial Building 253-261 Hennessy Road WanChai, HK.

Address: No.65 Science Avenue,HI-TECH Zone,Zhengzhou,China.